In the world of robotics, Offline Programming (OLP) has come a long way in a short time, and the global pandemic has jumpstarted more innovation. Industrial robots have evolved from complex assembly line robots to collaborative robots (“cobots”) that work side by side with their human counterparts. As technology advances, the industry is seeing many changes and enhancements to OLP.

In our previous article we examined versatility as an important future trend in OLP. In this article, we will examine smart machines.

As IIoT and machine learning become more sophisticated and user-friendly, users want robots with machine and robot intelligence embedded into the operating systems. Programming a robot using a conventional teach pendant is time-consuming, cumbersome, and subject to user error. Depending on the robot cell configuration, reaching all the points with the robot arm in teach mode can be impractical, or even dangerous.

When using an OLP, all the programming can be completed before the robot’s installation. The operation can be tested and issues resolved, so that installation and setup can be completed in a few hours or days rather than weeks. Program edits can be performed within the OLP software, rather than shutting down production to change points in teach mode on the pendant. The next function can be queued up while a current task is already in progress. With the right OLP and minimal training, anyone can program a robot, which is advantageous given skilled labor shortages.

Maximizing ROI is a primary objective in manufacturing, so, for example, it is far more cost-effective to have a welder embed their process experience into a powerful and easy to use programming software, than trying to find a programmer who is also experienced in welding.

Another advantage of OLP is the ability to troubleshoot, upload, and program from anywhere through the IIoT using a computer or tablet. Rather than shutting down the production line to determine what is wrong, advanced troubleshooting data and reporting can help programmers solve the problem quickly without an in-person trip.

In tandem with this, there will be a continued push for efficient analysis of all the data the robots generate, whether regarding errors, exceptions, or production reports. It’s not enough to produce the data; companies will need a means of analyzing, interpreting, and storing that data, bringing new challenges to both designer and user. While things like kinematic errors will continue to happen on the floor, the ability to pinpoint location, anticipate, and resolve the issue could significantly reduce production errors and downtime.

Want to learn more about OLP? Check out About Offline Programming for robots.

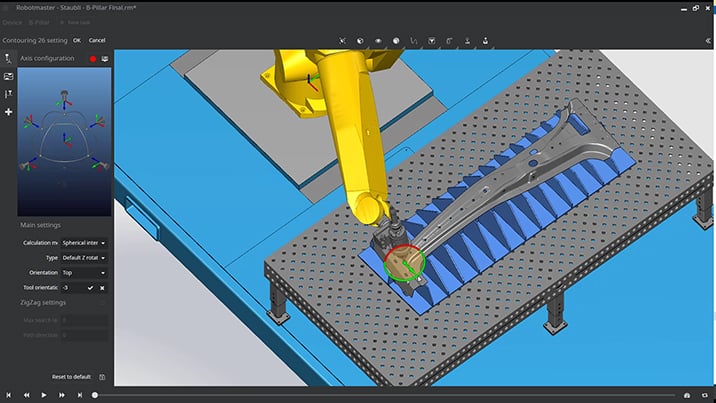

Robotmaster®, a Hypertherm brand, is an offline programming software for robots that helps manufacturers maximize productivity on production runs of all sizes. Robotmaster makes programming parts of any complexity quick and easy as a result of its integrated CAD/CAM functionality. This intuitive and powerful solution is designed with process experts in mind reducing the need for programmers and robotic expertise.