In the world of robotics, Offline Programming (OLP) has come a long way in a short time, and the global pandemic has jumpstarted more innovation. Industrial robots have evolved from complex assembly line robots to collaborative robots (“cobots”) that work side by side with their human counterparts. As technology advances, the industry is seeing many changes and enhancements to OLP.

Previously we examined trends such as versatility, smart machines, and the importance of simplicity, accessibility, and simulation capabilities in the robotics and OLP world. In this article, we will examine the importance of achieving competitive advantages.

Competitive advantage OLP and robot integration has become a competitive market, requiring participants to innovate to maintain their competitive advantage. Robotmaster provides manufacturers and integrators the features needed to stay ahead of their competition; and that requires constant innovation. For example, in many manufacturing facilities, brand-agnostic OLP solutions will continue to be an invaluable sales tool, offering the ability to quickly format/adjust a solution to deliver an accurate time/cost estimate for customers.

Often, robot OEMs provide their own brand of OLP software which is compatible with their specific brand. However, a manufacturing facility that has multiple robot brands might be better suited to a brand agnostic OLP solution, an all-in-one solution to program all robot brands. At the same time, a custom OLP solution may not make sense in a facility using automation that doesn’t change a lot over time. There will always be the delicate balance between customization to meet a customer’s unique challenges and pricing the solution out of reach for small or medium manufacturers.

As manufacturing facilities become more familiar and comfortable with robotic integrated solutions that can enhance productivity, perform hazardous, tedious, or dangerous tasks, or automate repetitive operations so employees can use their skills elsewhere, the pressure to innovate, adapt, and evolve will endure. OLP continues to become more agile and robust, providing time saving solutions to many robotic integration challenges.

Want to learn more about OLP? Check out About Offline Programming for robots.

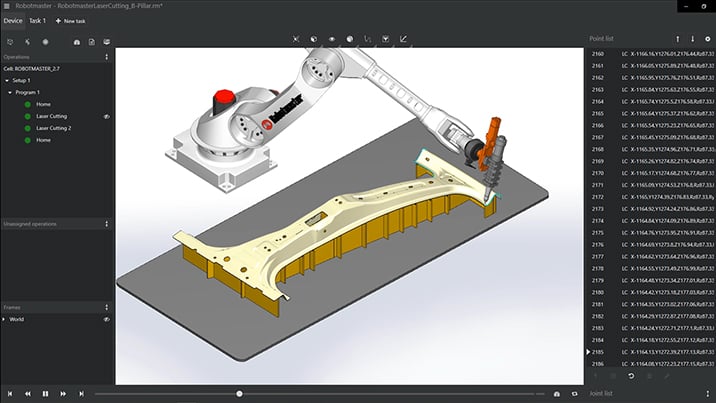

Robotmaster®, a Hypertherm brand, is an offline programming software for robots that helps manufacturers maximize productivity on production runs of all sizes. Robotmaster makes programming parts of any complexity quick and easy as a result of its integrated CAD/CAM functionality. This intuitive and powerful solution is designed with process experts in mind reducing the need for programmers and robotic expertise.