Automation is something we had been wanting to do for over a decade...automation standardizes the finish, the consistency, and improves our cycle time.”

Saravanan Rajaram, Mechanical Engineering

McStarlite

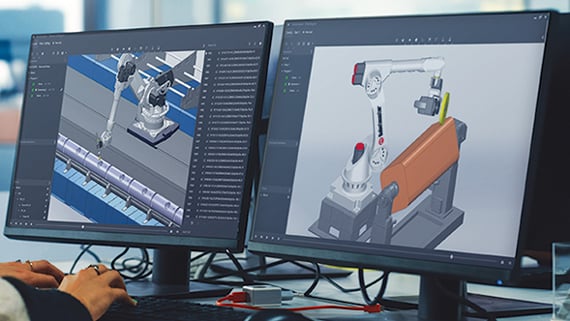

Read moreRobotmaster® is an offline programming software for industrial robots that seamlessly integrates cell layout and planning, CAD to path programming, program optimization, simulation and code generation. Robotmaster is a powerful and easy-to-use robot programming method ideal for:

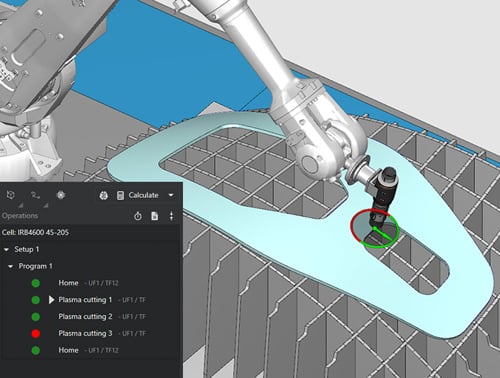

Programming high-mix, low-volume production

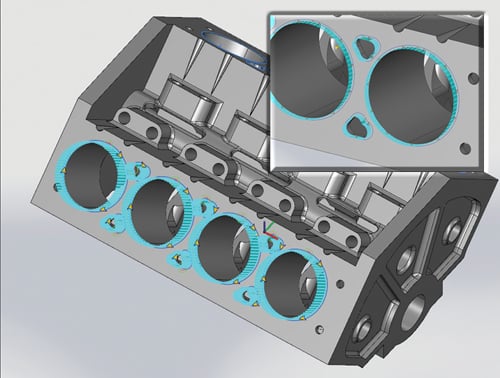

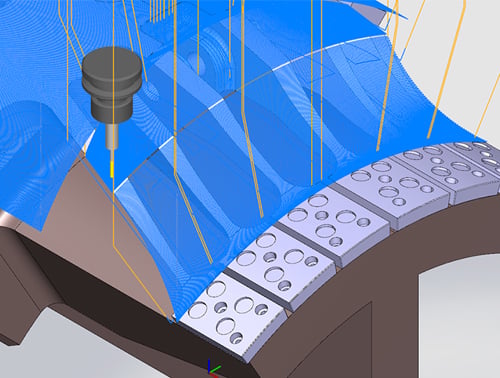

Automating complex shape processes

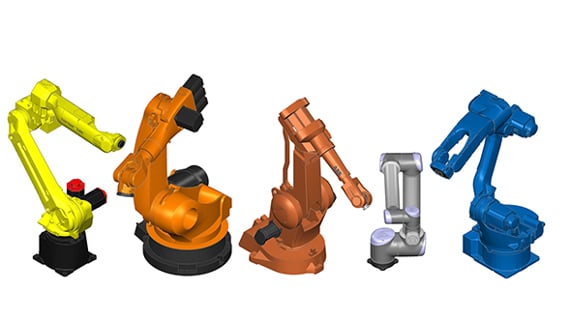

Programming a variety of robot brands

Increasing efficiency and lower costs

Users with minimal to no programming and robotics expertise

Robotmaster blends powerful tools, essential for programming complex applications and shapes, with intelligent and intuitive features enabling users of all experience levels to program with confidence.

User-friendly editor with powerful creation and validation tools for engineering your entire robotic work cell.

Intelligent pathing modules to handle industry leading robotic applications without requiring CAD/CAM skills.

Single-click path optimization and error-correction tools.

Bridge the gap between CAD/CAM and robotics with embedded technology to seamlessly translate CAD/CAM trajectories into robot trajectories.

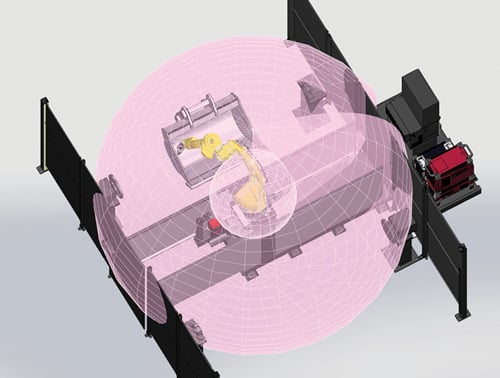

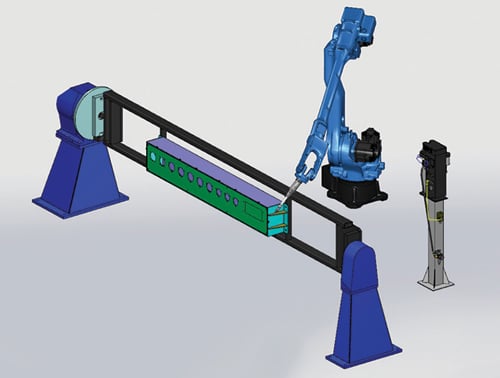

Powerful tools for programming external axis including rails and rotaries to work on even the largest and most complex work pieces.

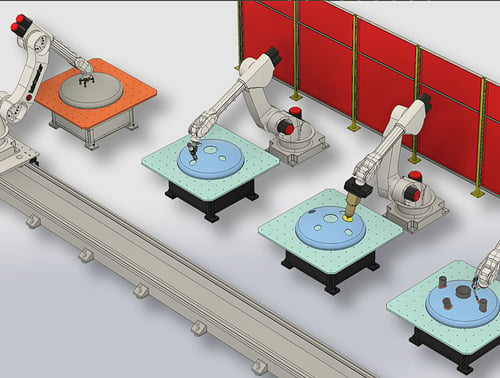

Efficient multi-arm cell design, path planning and optimization, load distribution, error detection and resolution tools that drastically improve the programming process, shorten cycle times, and boost output.

Contact us to see if your brand is supported.