Automation is something we had been wanting to do for over a decade...automation standardizes the finish, the consistency, and improves our cycle time.”

Saravanan Rajaram, Mechanical Engineering

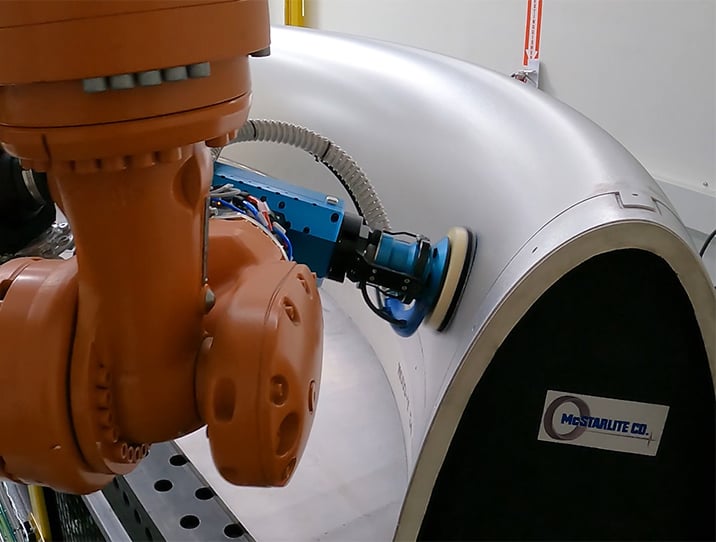

McStarlite

Read more

Surface grinding and finishing, such as sanding, grinding, polishing, and other finishing processes are time-consuming and labor-intensive processes that require the operator to have stamina and technical skill to perform manually.

Robotic automation solutions are increasingly used to perform these tasks as they offer grinding and finishing process repeatability and consistency around the clock. Industrial robots help supplement the skilled labor shortage and keep workers away from hazardous grinding process environments including dust, fumes, and vibration as well as ergonomics related injuries. Automation solutions make it easier to attract skilled labor with a more comfortable and safer work environment.

Programming robotic grinding, sanding, deburring, and polishing manufacturing processes with Robotmaster® offline programming software, ensures the optimal material removal finish is achieved while optimizing operations and reducing the process expertise required to achieve high quality finishes.

Automated surface grinding applications and robotic finishing can process a wide range of materials, including metals, composites, and even certain plastics and wood.

A grinding robot or finishing robot cell follows the exact same process every time, reducing human error and ensuring optimal, high-quality finishes.

Whether you’re performing material removal and finishing applications for aerospace, and automotive components, automation via an industrial robot or a cobot paired with Robotmaster will result in consistent quality, improved cycle times, less downtime, and higher throughput than manual processes.

Automatically generate paths from the CAD model and select the path pattern from a library of recipes to achieve the desired results

Program part to tool configurations and optimize for minimal wrist rotation and to maintain the orientation between the part edge and the sander, grinder, or other abrasive end of arm tooling constant

Ensure program feasibility on large parts with complex paths

Easily adjust process-specific parameters such as feed-rates, RPM, forces, passes, and penetration depth to tailor the program to the specific surface finishing requirements

Precisely control abrasive end effector tool orientations to achieve optimal abrasive surface contact, ensuring a uniform surface finish across all surfaces

Optimize the program paths to avoid errors and collisions, safeguarding both the robot and the workpiece

Visualize depth during simulation to ensure accurate surface finishing

Eliminate the need to rework parts, saving time, costs, abrasives, and resources

Intercam SA is the distributor of Robotmaster for non-cutting applications. Intercam SA provides sales, training, services, and support for Robotmaster and offers value-added add-on modules to broaden Robotmaster's capabilities outside of Hypertherm® cutting applications. For solutions in robotic grinding and finishing, contact Intercam SA.